usp class vi vs iso 10993

The first part of the ISO 10993 standard Biological Evaluation of Medical Devices. Depending on the devices use the sterilization process might.

Unlike other rubber standards theres no one standard that engineers use for an approval.

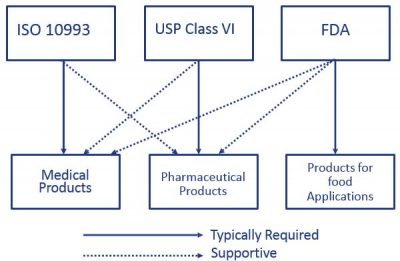

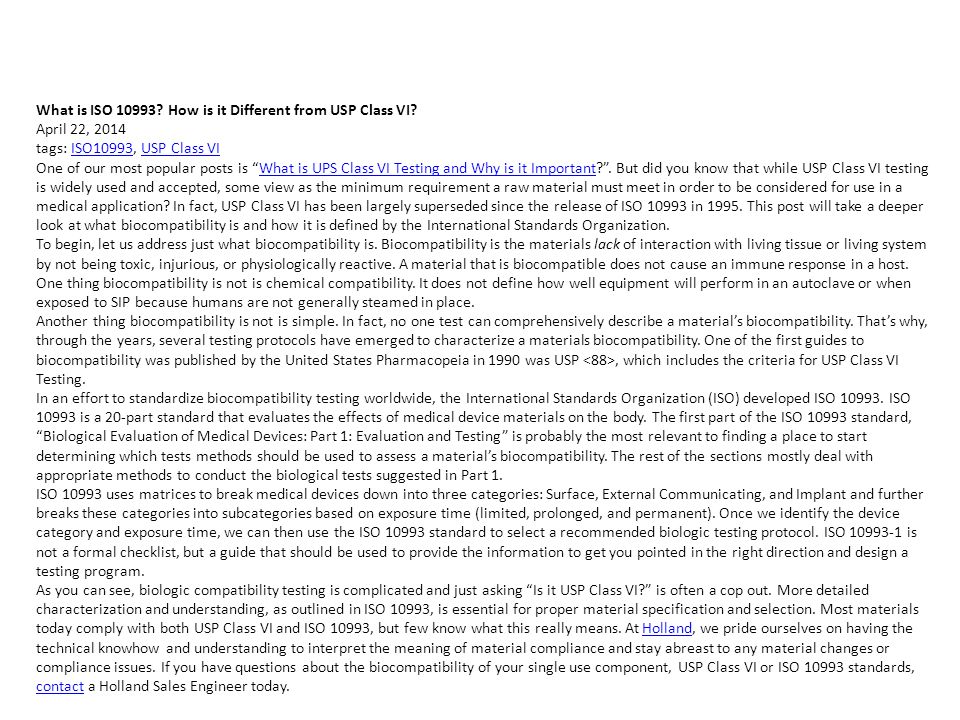

. ISO 10993 is a 20-part standard that evaluates the effects of medical device materials on the body. USP class qualification was a key method for establishing material biocompatibility at least as far back as 1976 until the 1987 adoption of the Tripartitite Agreement. If yes to the first question then USP Class VI is not a relevant qualification for it.

That said the lack of risk assessment in USP Class VI can be a problem. Biological evaluation of medical devices Part 1. USP Class VI.

In an effort to standardize biocompatibility testing worldwide the International Standards Organization ISO developed ISO 10993. Take an ASTM D2000 call out. Tripartite introduced the first expectations of biocompatibility testing specifically focused on device-related material.

USP Class VI testing alternatively can be. Biocompatibility testing biocompatible materials biocompatible rubber ISO 10993 medical molder medical molding medical silicones USP Class VI. Testing is commonly done as per USP which requires three types of.

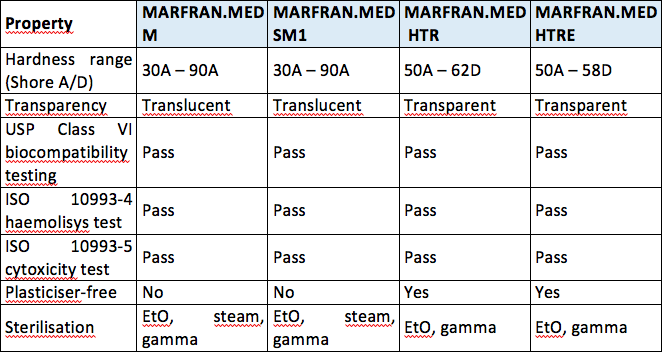

For most patient-contact applications a material that meets US Pharmacopeia USP Class VI andor ISO 109933 will be required. The International Organization for Standardization develops and publishes documents that provide requirements specifications guidelines or characteristics that can be used consistently to ensure that materials products processes and services are fit for their purpose The ISO standard for medical grade materials is 10993. For this reason the FDA provides a standard 21 CFR1772600 defining allowable rubber compound ingredients and extractibles based on toxicity and carcinogenicity.

USP Class VI vs. The ISO 10993 set entails a series of standards for evaluating the biocompatibility of medical devices to manage biological risk. A rubber compound has set physical parameters it needs to meet.

Depending on the devices application and how the cable components will interact with the patient this higher level testing may not be needed. USP class VI versus ISO 10993. USP Class VI testing is conducted by producing an extract of the product with different extraction fluids such as polyethylene glycol and vegetable oil and injecting it in specimen rabbits and mice in vivo alive to observe the biological response to the extract.

Class VI and ISO 10993 are recommendations for testing based on the use of the final device. So does ISO 10993. Many medical molding applications use silicones but not.

USP Class VI ISO 10993-5 Cytotoxicity In-Vitro ISO 10993-3 Ames Genotoxicity ISO 10993-11 Systemic Toxicity In-Vivo ISO 10993-4 Hemolysis Indirect European Pharmacopeia 329. May 1 2009. Its possible that a USP Class VI material can also.

USP Class VI Regiment Irritation Systemic Injection Implantation 1 week Biological Evaluation Plan BEP. Medical Molding and Biocompatibility Testing of Medical Devices Standards EN ISO 204172021 - Medical devices - Information to be Use of ISO 10993-1 Biological evaluation of medical ISO - ISO 18562-12017 - Biocompatibility evaluation of ISO -. You might establish biocompatibility via making the device of a Recognized Consensus Standard material using a validated process that does not degrade that material or by ISO 10993 testing.

Rob Pruyn July 30 2020 Custom Products Medical Devices Molding Services. For the purpose of the ISO 10993 family of standards biocompatibility is defined as the ability of a. Typical physical properties of C-Flex Property ASTM Method Formulations Value or Rating.

Testing to the highest ISO-10993 standards can add months of time and be very costly according to the Medical Device Testing Guide by Toxikon Inc. Both ISO 10993 and USP Class VI define testing requirements for biocompatibility the ability of a material to perform a desired function without causing adverse effects on the human body. These documents were preceded by the Tripartite agreement and is a part of the international harmonisation of the safe use evaluation of medical devices.

ISO-10993 Standard USP Class VI Standard Other Industry Standards Page 2 Evaluation of Biocompatibility Page 6 Biomerics Polyurethane Resin Families Page 8 Quadrathane ALC Resin Results Page 9. However Class VI also requires subacute toxicity and implantation effects which many ISO 10993 categories do not. USP Class VI demands an intracutaneous irritation test.

Evaluation and testing within a risk management process. Most applications are fairly benign to elastomers. Medical Silicone Rubber Molding and Silicone Rubber Mold Materials.

Typically the terms USP Class VI or ISO 10993 materials are used.

Understanding Food Grade Vs Biocompatibility For Medical Device Materials Medical Product Outsourcing

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants

Iso 10993 Vs Usp Class Vi Medical Molding And Biocompatible Rubber

What Is Iso 10993 How Is It Different From Usp Class Vi Ppt Download

Material Selection Medical Injection Molding Xcentric Mold

Iso 10993 Vs Usp Class Vi Medical Molding And Bicompatible Rubber The Rubber Group

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants

Usp Class Vi Certification Presco Marking Products And Engineered Films

Regulatory Guidelines For Biocompatibility Safety Testing Mddionline Com

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants

Brilliant Mind The World Of Tubing For Medical Use Medical Plastics News

Usp Class Vi Foster Corporation

Regulatory Guidelines For Biocompatibility Safety Testing Mddionline Com

What Is Iso 10993 How Is It Different From Usp Class Vi Ppt Download

Material Selection Medical Injection Molding Xcentric Mold

Understanding Food Grade Vs Biocompatibility For Medical Device Materials Medical Product Outsourcing